Timeline: August 2021 – May 2022

Institution: Department of Mechanical and Mechatronic Engineering and

Advanced Manufacturing, The California State University - Chico

As the global demand for food increases, traditional labor-intensive agricultural methods are becoming unsustainable. This project tackled that challenge by developing a parallel-kinematic robotic system with a compliant soft-material end-effector, capable of performing delicate pick-and-place tasks for food processing and packaging.

The system combined mechanical design, manufacturing, and computer vision, aiming to automate repetitive manual work while maintaining the precision and care required for handling agricultural produce.

We sought to design a robotic system that:

- Accurately identify, pick, and place produce using computer vision.

- Maintain precision and compliance to avoid product damage.

- Integrate seamlessly with industrial robotics infrastructure (Omron Hornet 565).

- Be reliable and repeatable with minimal human interaction.

This meant combining mechanical engineering and software integration into a single cohesive platform.

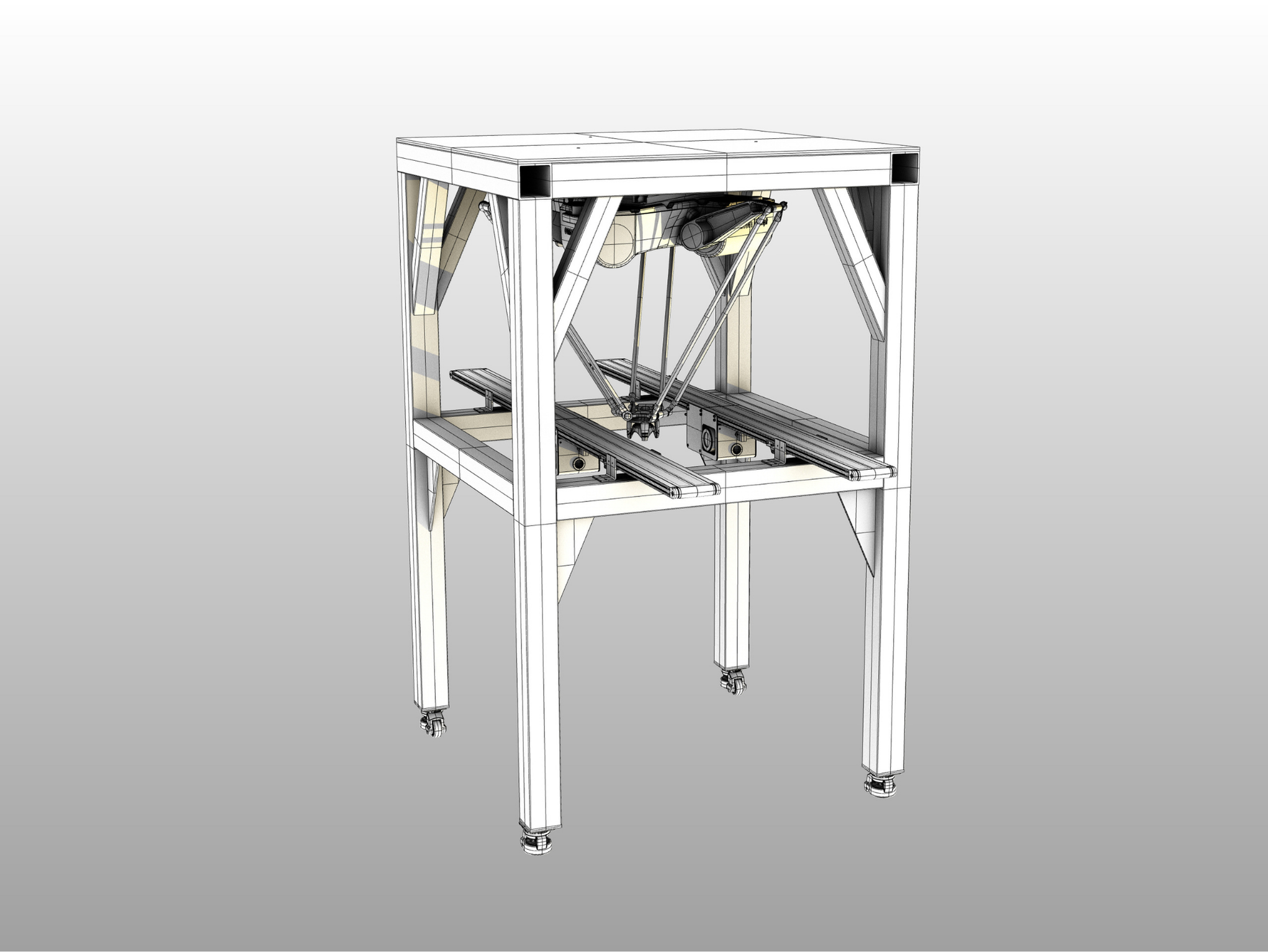

The project explored multiple design paths covering chassis structure, camera and computer selection, and communication protocols. Initial chassis designs used aluminum extrusion for modularity but were later replaced due to rigidity considerations. The final design was built from ASTM-A500 steel tubing and plating, offering superior stiffness and durability under cyclic robotic loading.

I was responsible for the structural modeling, simulation, and optimization of the chassis, as well as validating all

mechanical assumptions through FEA and analytical comparison. In addition, I coordinated the sourcing and delivery of

materials, and managed the manufacturing and welding process, ensuring structural accuracy during fabrication, a

critical step given that the steel tubes used were extremely heavy and required precise, reinforced connections.

After welding, the structure consisted of two main assemblies: the chassis body and the top plate. I performed precise

measurements and defined all hole placements for both the screws connecting the top plate to the chassis and those

securing the robot to the top plate, guaranteeing structural stability and alignment. Once assembled, the robot/top plate assembly was

mounted using a winch system onto the 7-foot-tall chassis, where hole alignment was perfect, and the entire system was

successfully integrated into a single, rigid assembly.

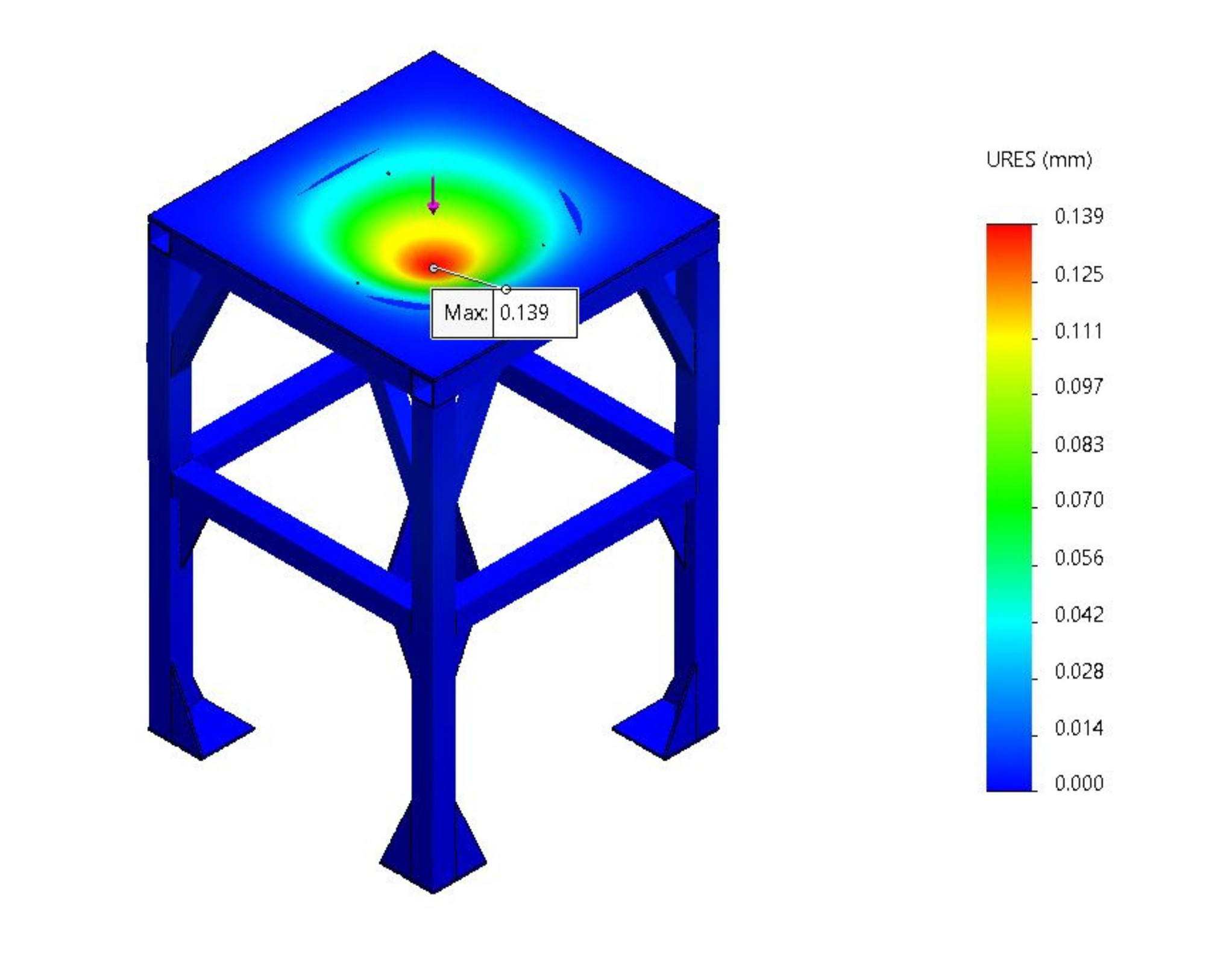

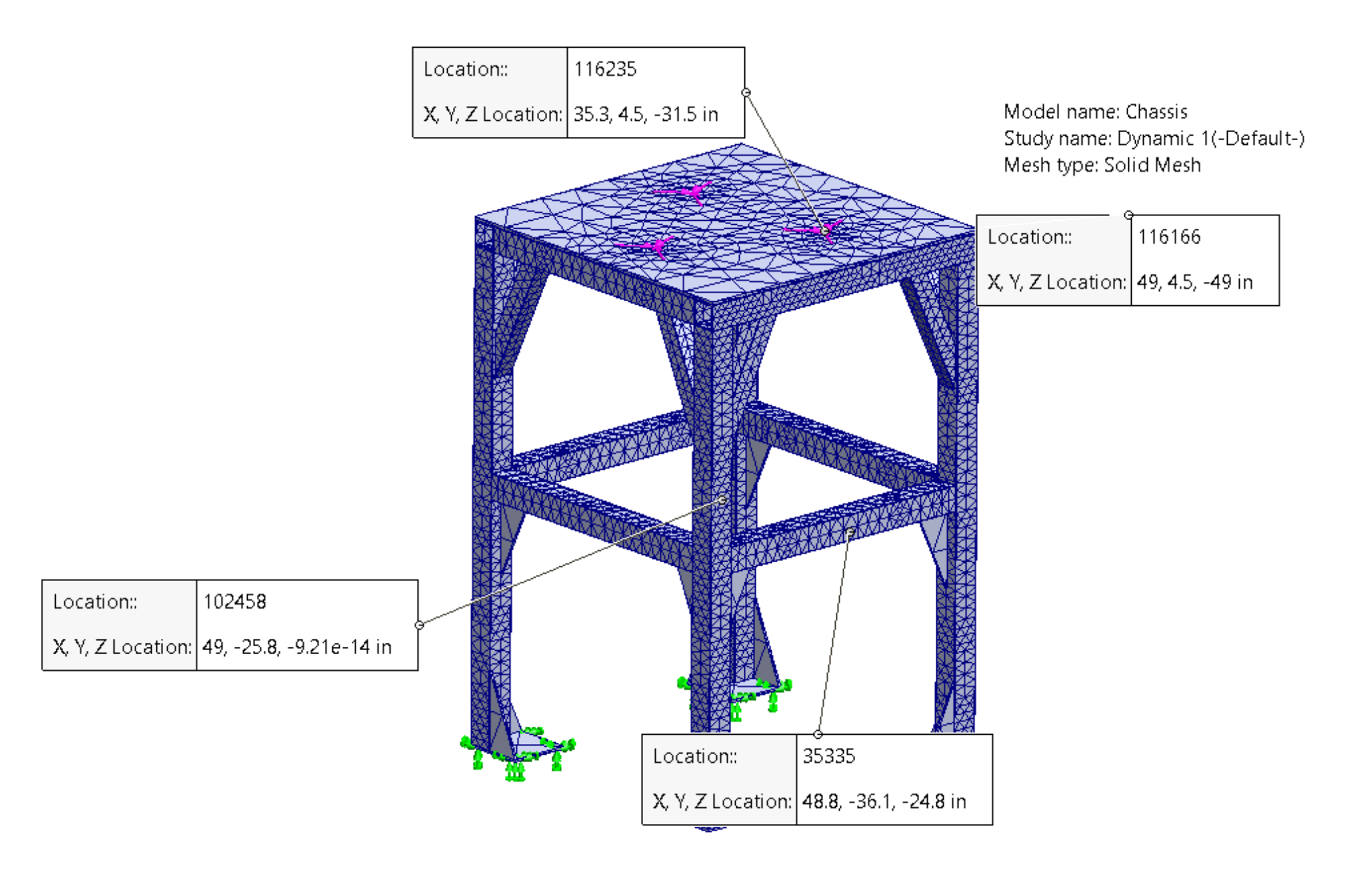

To verify performance, I conducted both static (hand-written + Solidworks) and dynamic (Solidworks) FEA studies.

Static Analysis:

Used analytical equations to predict plate deflection under the

robot’s weight.

Results: analytical = 0.1557 mm deflection; FEA = 0.139 mm deflection, confirming high

correlation between the two methods and successdul plate thickness and material selection.

Dynamic Analysis:

Performed frequency-response simulations using linear dynamic and harmonic studies.

Input: cyclic loading generated by end-effector motion.

On the other hand, a very crucial aspect was altering the study’s properties to a number of 10 Frequencies ranging from

8.4 to 150 Hz [“Industrial Robotics Automation Catalog, Product Datasheets.” Omron Industrial Automation], along with a

bandwidth of 0.6 around each frequency and a Linear Interpolation.

Identified safe operational frequency bands between 37–70 Hz and 120–140 Hz, ensuring structural

resonance avoidance and stability during continuous operation.

The end-effector was the centerpiece of this project; a four-finger compliant gripper 3D-printed with NinjaFlex filament. This soft material enabled gentle yet controlled gripping of produce, balancing flexibility and precision.

The design was based on human grasp taxonomy research, ensuring effective contact points and adaptive deformation. The pneumatic actuation system provided consistent force control across varying object shapes and textures, ideal for food handling.

The system combined four key technologies:

- Omron ACE (Automation Control Environment)

- OPC Infrastructure

- OpenCV Algorithms (Python/C++ on VS Code)

- NVIDIA AGX Xavier SBC (Ubuntu 18.04)

Through the OPC framework, data seamlessly flowed between the SBC, ACE, and MATLAB, enabling synchronized visual recognition and robotic motion. The system achieved > 90 % accuracy in 2D image processing, surpassing the performance goals set at the start of the project.

As part of a multidisciplinary team of four engineers, I led the:

- Mechanical design, simulation, and assembly of the chassis.

- Design and integration of the compliant gripper with the delta robot.

Faculty Advisor: Dr. H. Sinan Bank

Team Members: Maryam Nassar, Travis Bybee, Joe Karam, Roque Martinez

The project demonstrated how parallel-kinematic robotics and soft materials can transform agricultural automation. As a first step toward an Industry 4.0 system within the Omron CoLab, the setup was designed for continuous improvement and future integration into a smart factory ecosystem featuring cyber-physical systems.

Planned extensions include:

- Implementing object-depth detection for 3D recognition.

- Exploring alternative gripper modalities such as vacuum pads for diverse produce handling.

- Expanding communication layers to enable full autonomous coordination among multiple robotic

systems.

Problem: Agricultural packaging required repetitive, delicate labor unsuitable for traditional

automation.

Method: Designed a steel-framed robotic platform with a soft, compliant gripper and integrated

computer-vision control.

Result: A validated, high-accuracy robotic pick-and-place system ready for adaptation into

Industry 4.0 agricultural environments.

Credits:

Developed at the California State University, Chico

Department of Mechanical and Mechatronic Engineering and Advanced Manufacturing

Faculty Advisor: H. Sinan Bank

Team Members: Maryam Nassar, Travis Bybee, Joe Karam, Roque Martinez