Timeline: August 2021 – May 2022

Institution: The Pennsylvania State University

This collection of projects explores Design for Additive Manufacturing (DfAM), applying design

principles, engineering analysis, and creative problem‑solving to push the boundaries of what

additive manufacturing can achieve.

Each project focused on a different aspect of the DfAM philosophy, from printing limitations and

part consolidation to topology optimization, metal additive design, and education in AM.

In additive manufacturing, the same CAD model can produce vastly different outcomes depending on

printer settings such as orientation, layer thickness, material, and temperature.

This project analyzed the limitations of Fused Deposition Modeling (FDM) using a

MakerBot Replicator 5th Generation by focusing on two dependent variables:

‑ Minimum feature size

‑ Minimum assembly clearance

And two independent variables:

‑ Orientation

‑ Geometry

A benchmark artifact was designed to systematically test these parameters, revealing the

thresholds for reliable FDM printing.

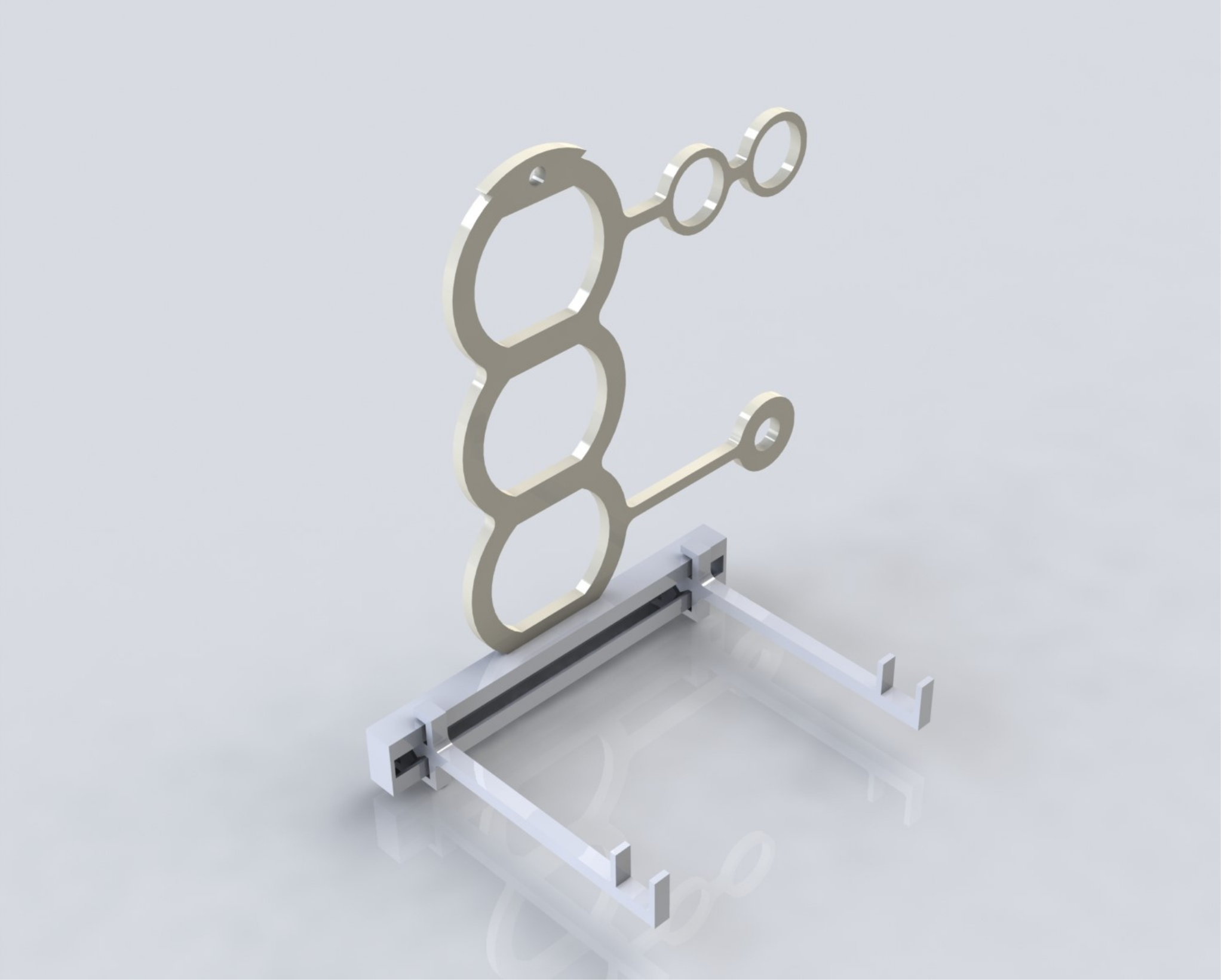

This project tackled everyday inefficiencies in charging electronics. The challenge: redesign a phone outlet holder that consolidates multiple functions: organization, charging, and aesthetics, into a single printable part.

The final design achieved:

‑ Part consolidation: reduced from multiple components to one.

‑ Weight reduction: optimized geometry for material efficiency.

‑ Enhanced usability: holds the phone securely, routes the cable cleanly, and fits snugly onto

the outlet without adhesives.

It served as a study in opportunistic DfAM, where constraints become design opportunities for improved functionality and appearance.

To demonstrate the power of topology optimization, this project focused on redesigning a launch

support attachment bracket for ULA’s Atlas V rocket.

The goal was to minimize structural weight while preserving load‑bearing performance, directly

translating to increased payload capacity to orbit.

I compared the intuitive design versus TO‑generated geometry, analyzing manufacturability,

stress distribution, and material efficiency through CAD and simulation.

This project highlighted how additive manufacturing and TO enables aerospace‑grade lightweighting that

would be impossible with traditional subtractive methods.

This project combined metal additive manufacturing with biomedical engineering, redesigning a

mid‑shaft femoral fracture fixation plate to optimize both strength and bone integration.

Using Ti‑6Al‑4V (Titanium Alloy) and Electron Beam Powder‑Bed Fusion (EB‑PBF), we re‑engineered

the plate for enhanced biomechanical performance.

My Role:

I led the design and CAD modelling in SolidWorks and Rhino (parametric design), using nTopology for advanced lattice

and topology optimisation.

After developing the base geometry, I integrated a gyroid lattice structure to reduce weight,

promote osseointegration, and maintain structural strength under cyclic loads.

With additive manufacturing rapidly evolving, one of the most critical challenges is preparing

new engineers and designers to think additively.

This research focused on improving DfAM education for beginners by developing strategies and

frameworks that help students:

‑ Understand all AM processes and their trade‑offs.

‑ Integrate engineering fundamentals with design creativity.

‑ Apply problem‑solving and digital fabrication tools effectively.

‑ Think critically about manufacturability from concept to production.

The outcome proposed a more user‑friendly, project‑based learning structure to make DfAM principles accessible and intuitive for newcomers to the field.

Problem: Traditional design processes fail to exploit the full potential of additive

manufacturing.

Method: Researched and applied DfAM principles across multiple domains: structural optimisation,

material experimentation, part consolidation, and education.

Result: A portfolio of tested methods and real‑world prototypes demonstrating how DfAM bridges

engineering performance and design innovation.

Credits: Developed at The Pennsylvania State University.